There really is a dazzling variety of books out there, and they come in all colours, shapes and sizes. There are hardbacks, softbacks, perfect-bound, saddle-stitch, Ota-bound, and so much more.

This can be a little overwhelming for authors of course, particularly those venturing into self-publishing for the first time. Authors can be left wondering what particular type of book, or what particular production method, is best for them.

We are very passionate about our method of book binding, which is called Ota- binding. Having been in the industry since the 1980s, we have perfected our craft. It is the method that produces the best quality books for our clients, and creates the most satisfying and rewarding reading experience for their readers. Before we get to the finer details however, allow us to take you through the various stages in the production process – trust us, don’t let the jargon put you off, book production is fascinating!

The first stage in book creation is the text block, or ‘book block’. This is the ‘block’ of pages, the pages of text in the book, gathered together.

After your book block is formed, the next step is your choice of glue. Most printers and book producers these days will opt for a hot glue called EVA, where the ‘book block’ is fused together and glued to the cover through a process known as ‘hotmelt’. One advantage of using hot glue is it hardens very quickly, meaning the printer can mass-produce a large quantity of books over a short period of time. It is also much cheaper than the more traditional cold glues.

We at Lettertec however use cold glue. A durable, environmentally-friendly cold glue called PVA to be specific. It is more expensive than the cheaper, hot glue (EVA) but the trade-off is worth it, as the books produced through this artisan, bespoke method are superior.

Once the cold, PVA glue is applied, we have to wait twenty-four hours for it to harden. We feel however that what we lose in speed is more than made up for in quality. Hot glues like EVA have a limited lifespan, they become worn and brittle over time, often snapping and damaging the book in the process. Another problem with hot glue is you have to use large amounts of it to ensure the book is properly attached. Using more glue in attaching the book block to the cover and spine, causes the spine to become stiffer, meaning the spine will become creased and wrinkled over time.

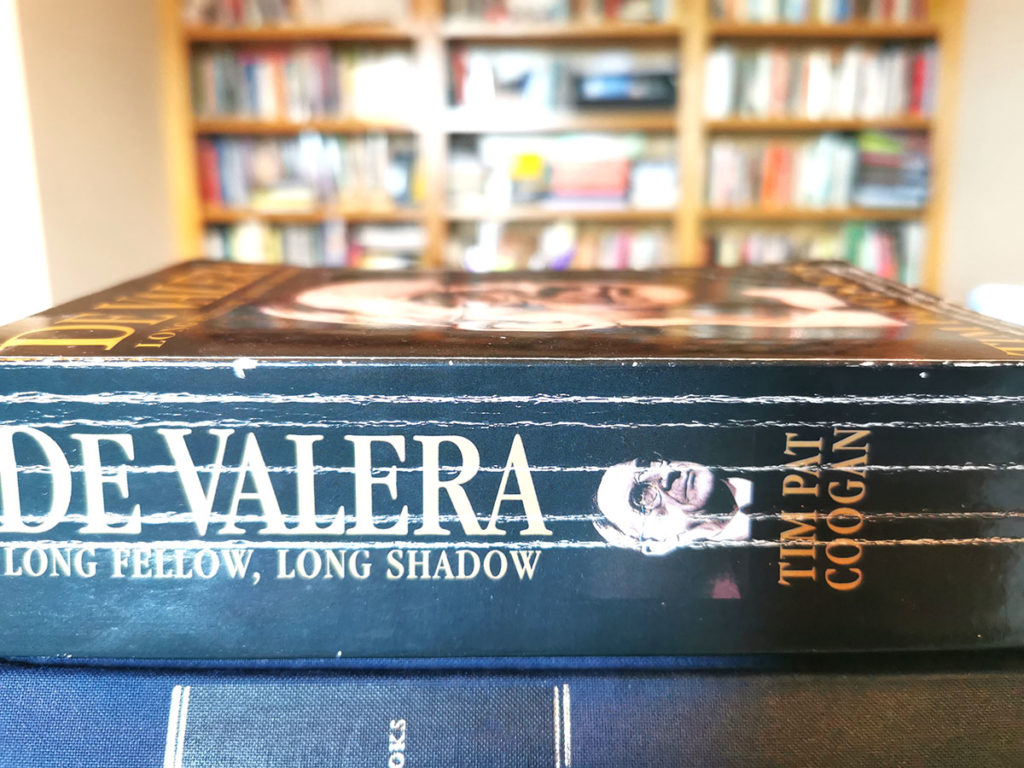

One good way of visualising what we mean is to browse through your own book collection at home, or through the books in your local library or bookshop. You will notice that some of the books’ spines, the older paperbacks especially, have become wrinkled and wizened; some are probably so wrinkled they resemble the bark of an old tree. This creasing and wrinkling is far more likely to happen if the printer uses hot glue. This has happened to the book pictured below for example.

We always prioritise quality in our book production methods. Books are physical objects after all, so it is important they look good on the shelf; smooth, beautifully designed spines with legible text will make an instant impression on readers and the book-buying public. The last thing you want is for a reader to be presented with a tattered, wrinkled spine, and for them to be unable to read the title.

The next stage in the book production journey is attaching your book block to the cover. This sounds straightforward, but it is in many respects the most crucial step in the entire process. Most printers and binders will attach the book block directly to the cover with hot glue. The again enables mass-production, in the respect you can produce a large quantity of books within a relatively short time-frame.

The image below is a good illustration of this method. Pictured is a standard mass-market paperback, bound with hot glue and affixed directly to the cover. It is fast, quick and simple. Having been in the book production business since 1983 however, we are passionate about providing our authors with something that little bit more special, more bespoke.

We use a bespoke book production method know as ‘Ota-binding’, pioneered by Finnish printers and book specialists Otava.

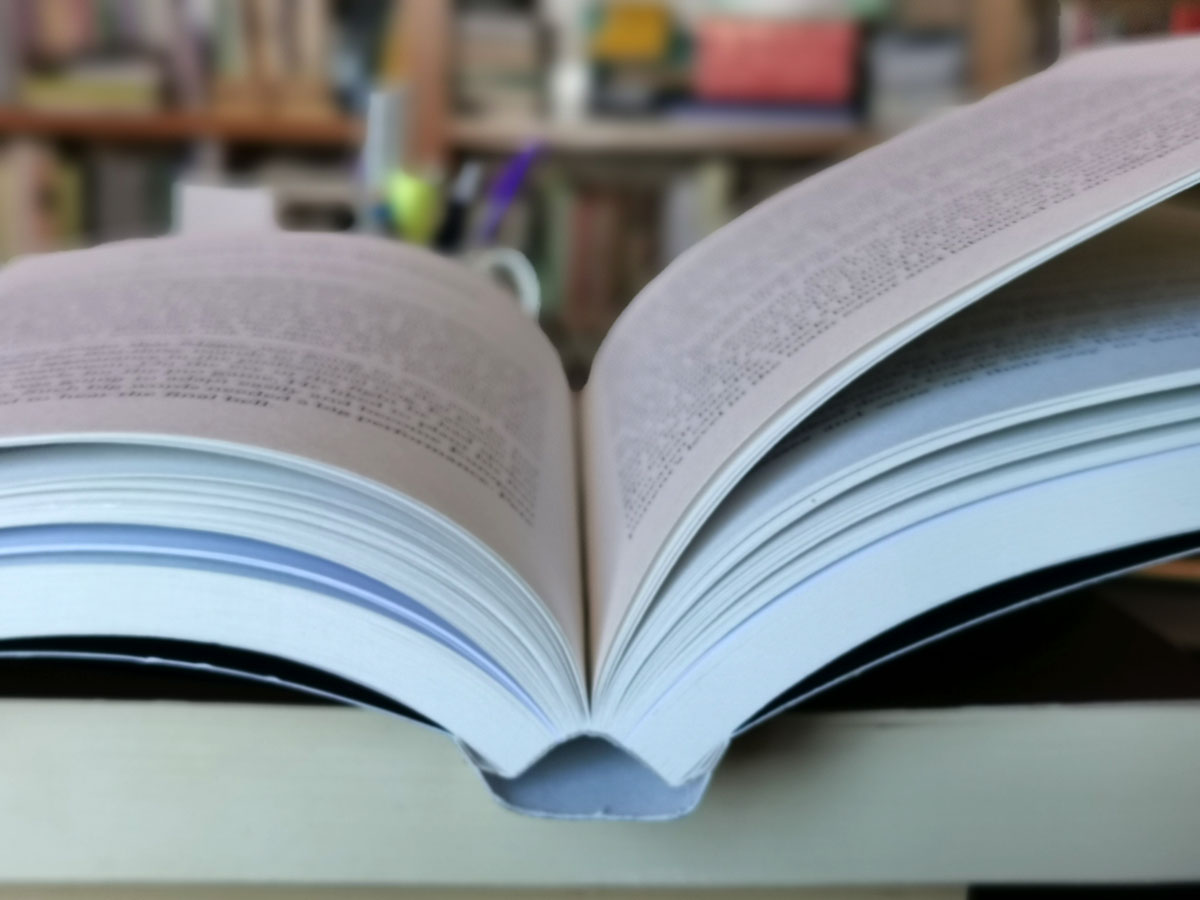

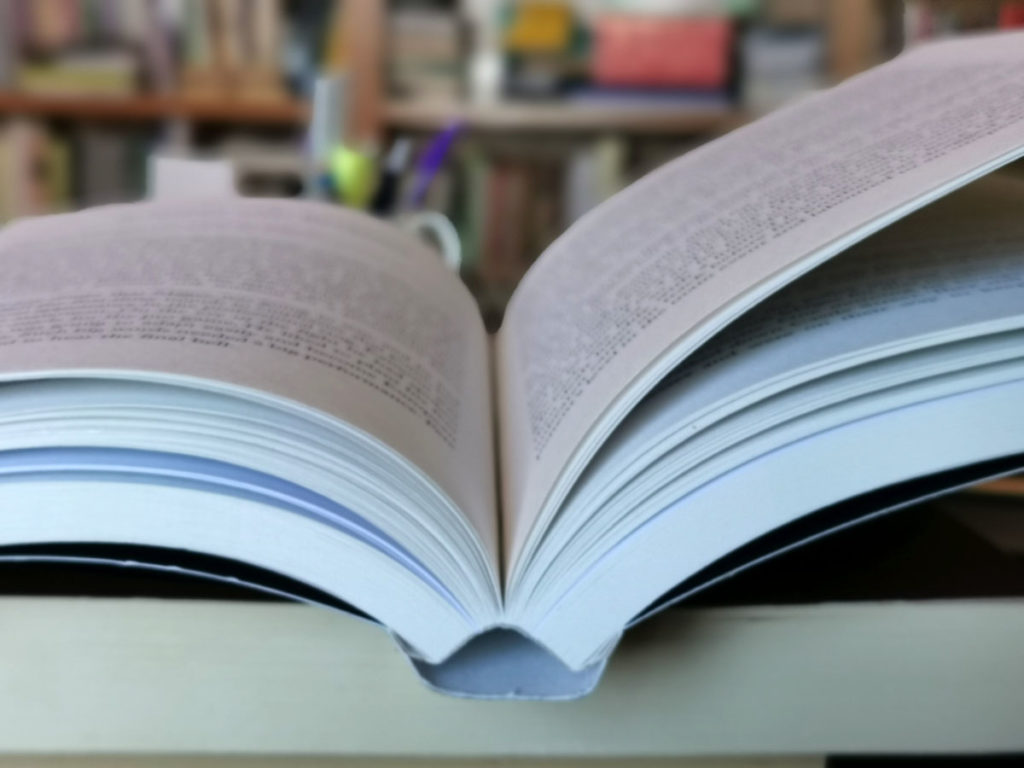

Rather than the book block affixed to the cover, we wrap it in a protective material know as a guaze or mull, and attach the cover to the two end pages. This leaves a small little space between the book block and the spine, as you can see in the images below. This sounds small, but it makes a dramatic difference to the physical quality of the book, and as a result the reading experience for readers. It allows the reader to lay the book flat while reading, so the book can be appreciated without constantly having to manually flatten the pages. It prevents what is known in the industry as the ‘rat trap’ effect. Most readers will be familiar with the annoyance of opening a book and starting to read, only for the book, as if it had a mind of its own, to flap shut. See some examples of Ota- binding in the images below.

We feel these bespoke methods of book production (cold adhesives and Ota- binding) greatly enhance the books themselves, and as a result create a more satisfying experience for both authors and readers. The reader can retire to a quiet corner with their cup of coffee or tea and flick the pages of the book without having to wrestle with unwieldy pages. The book can remain on the shelf in the bookshop or library without wrinkling with age.

Our intention isn’t to criticise other printers and other methods; in an evolving industry, there are many different approaches, and one size certainly doesn’t fit all. Having been specialists in book production for so long however, we can confidently say that this is what works for us. These methods enable us to produce the best books for our clients, and provide them with the greatest chance of commercial and literary success.

Book production is a specialised craft, and we at Lettertec understand that more than most. We are happy to say that all our authors can avail of this unique, bespoke production method (Ota-binding) at no extra cost.